What is Power of The Shield you ask? Well, our Co-founders, a retired Firefighter/Paramedic and a State Trooper believe helping others is above everything else. Serving others comes naturally to us and is one of our core values. That is why we put our shield right in our logo. We wear it with pride every day.

If you are looking for a reliable and trustworthy garage flooring professional, look no further than The Garage Floor Company. Our trained and skilled professionals are dedicated to providing top-quality garage flooring solutions. The Power of The Shield will provide the best coatings and service in the industry.

Whether you’re looking to upgrade your home’s garage or give your commercial space a sleek, modern look, The Garage Floor Company has you covered. Our professionals will work closely with you to understand your needs and preferences and develop a custom solution tailored to your requirements. We take pride in our work and strive to exceed our client’s expectations.

We believe that a beautiful and functional garage is essential to your property’s overall value and appeal. That’s why we are committed to delivering exceptional service, quality workmanship, and unbeatable value to our clients. So if you’re in need of garage flooring solutions, contact us today to schedule a consultation.

When it comes to garage flooring, the preparation process is just as important as the coating itself. The coating may not adhere properly to the surface without proper preparation, leading to a shorter lifespan and potential issues. That’s why at The Garage Floor Company, we prioritize thorough preparation of the surface before applying any coating.

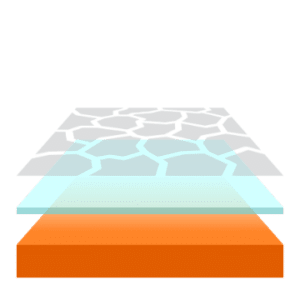

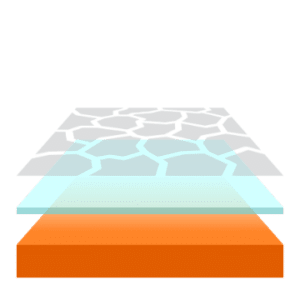

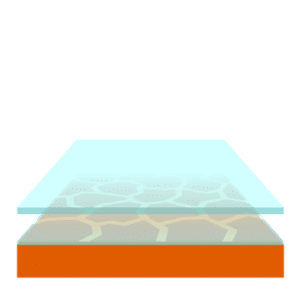

By prioritizing thorough preparation of the surface, we ensure that the coating we apply will look great and last for the long term. Our multi-step process, which includes a base coat, chips, and a clear coat, provides maximum durability and protection for your garage flooring. So if you’re looking for the best floor coating services, look no further than The Garage Floor Company.

Base Coat Application: The Garage Floor Company utilizes a proprietary Moisture Vapor Barrier epoxy base coat, which has superior adhesion properties compared to polyaspartics/polyureas and other epoxies. Completing this procedure ensures that the epoxy will not delaminate due to moisture vapors off gassing through the slab. Unlike other methods which do not have resistance to moisture, GFC’s Moisture Vapor Barrier base coat helps your floor resist the moisture coming from the ground.

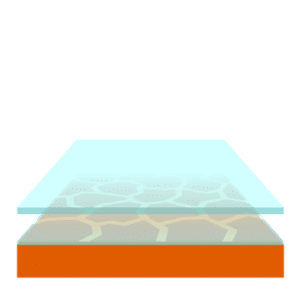

Polymer Chip Broadcast: Polymer chips are thoroughly and evenly distributed over the floor while the epoxy is still wet. This allows them to harden within the coating, providing texture and durability. GFC has standard colors in stock for the owner to choose from, or colors can be customized. The color on the floor comes from the polymer chips, not from the base coat of epoxy. If you are looking for a lower cost option, we offer a partial chip flooring option utilizing a colored epoxy base, a light chip broadcast, and a durable topcoat.

Clear Coat Preparation: After allowing for adequate bonding time, on the second day the clear coat preparation is completed. Because we broadcast 25% more chips than needed, any excess polymer chips are picked up and the floor is scaped in three directions to remove any partially attached chips. We also remove any chips and dust from the driveway so your new floor is as beautiful as possible.

Clear Coat Application: The final application step utilized by GFC is a combination system. A high solids polyaspartic top coat is used on exterior and garage applications to create a scratch resistant, very durable, and UV stable (non-yellowing). Most of our competitors do not use this system, and their top coats experience yellowing over time.

When it comes to garage flooring, the preparation process is just as important as the coating itself. The coating may not adhere properly to the surface without proper preparation, leading to a shorter lifespan and potential issues. That’s why at The Garage Floor Company, we prioritize thorough preparation of the surface before applying any coating.

By prioritizing thorough preparation of the surface, we ensure that the coating we apply will look great and last for the long term. Our multi-step process, which includes a base coat, chips, and a clear coat, provides maximum durability and protection for your garage flooring. So if you’re looking for the best floor coating services, look no further than The Garage Floor Company.

When it comes to garage flooring, the preparation process is just as important as the coating itself. The coating may not adhere properly to the surface without proper preparation, leading to a shorter lifespan and potential issues. That’s why at The Garage Floor Company, we prioritize thorough preparation of the surface before applying any coating.

By prioritizing thorough preparation of the surface, we ensure that the coating we apply will look great and last for the long term. Our multi-step process, which includes a base coat, chips, and a clear coat, provides maximum durability and protection for your garage flooring. So if you’re looking for the best floor coating services, look no further than The Garage Floor Company.

Clear Coat Preparation: After allowing for adequate bonding time, on the second day the clear coat preparation is completed. Because we broadcast 25% more chips than needed, any excess polymer chips are picked up and the floor is scaped in three directions to remove any partially attached chips. We also remove any chips and dust from the driveway so your new floor is as beautiful as possible.

Clear Coat Application: The final application step utilized by GFC is a combination system. A high solids polyaspartic top coat is used on exterior and garage applications to create a scratch resistant, very durable, and UV stable (non-yellowing). Most of our competitors do not use this system, and their top coats experience yellowing over time.

The difference between a Garage Floor Company floor and the status quo is night and day. Before we start, our team will review your plans for the room or garage.

From there, we’ll determine what materials best deliver your vision and create a gorgeous, enduring floor.

Our handiwork isn’t just found in garages, either. Customers have counted on us to deliver long-lasting, eye-catching floors in car dealerships, aircraft hangars, restaurants, and other retailers. We’re ready for perfect flooring installation that you need.

We specialize in transforming commercial spaces with durable and stylish commercial flooring solutions using industrial–grade epoxy floor coating that will enhance your business’s appearance and functionality.

Our team of experts will work with you to choose the perfect flooring option for your business, whether you need something durable for high-traffic areas or a stylish option to make a statement. We offer a wide range of materials, colors, and finishes to fit any aesthetic and budget.

With our commercial flooring services, you’ll get more than just a beautiful floor. You’ll also get a floor built to last, with materials and installation techniques that can meet the demands of a busy commercial space.

So are you ready to upgrade your business with our commercial flooring services? Give us a call today to schedule a consultation and start bringing your vision to life.

Hear from our Raving Clients!

EXCELLENTTrustindex verifies that the original source of the review is Google. Jeff was great to work with getting me a fast and accurate price quote and was very easy to work with when I had to push the schedule date back. John Massie and his install team were very detailed in every step of the process. The floor looks amazing. The whole team was friendly and polite. I would highly recommend.Posted onTrustindex verifies that the original source of the review is Google. Amazing work. Easy to work with and great communication.Posted onTrustindex verifies that the original source of the review is Google. Initially, had my floor done about eight years ago, and they did a great job! Recently had them come out and do a minor touchup… Great follow up and customer service!Posted onTrustindex verifies that the original source of the review is Google. Great experience and results With the garage floor company, Omaha! Jeff does fantastic work and many of my friends have already asked for his contact information! The garage floor looks amazing! Thank you!Posted onTrustindex verifies that the original source of the review is Google. Jeff and his crew at the Garage Floor company goes above and beyond and does an absolutely fantastic job!! What I asked for and what I wanted was very hard to achieve but Jeff had no problem making it turn out perfect!! Everyone that comes to my home and walks into the garage constantly talks about the garage floor coating and how phenomenal it looks so I would definitely recommend Jeff and the garage floor Company for any of your garage floor epoxy needs.Posted onTrustindex verifies that the original source of the review is Google. Floor looks great! The whole crew was very professional and great attention to detail. They have a trailer that they let me store all my stuff in which was a huge perk. Highly recommend.Posted onTrustindex verifies that the original source of the review is Google. I entrusted my garage floor to The Garage Floor Company Omaha for repairs, and the results were outstanding. Their expertise in garage flooring was evident as they transformed the worn-out surface into a sleek and durable masterpiece. Highly recommend their services for any garage flooring needs!Posted onTrustindex verifies that the original source of the review is Google. I can't express how happy I am with the garage floor service. The team was meticulous, and the epoxy coating they applied has made a world of difference in the aesthetics and functionality of the space.Posted onTrustindex verifies that the original source of the review is Google. The team did an excellent job fixing the imperfections in the concrete and created an amazing looking garage floor. They were fast and efficient and best of all they left no mess in the garage or the driveway.Posted onTrustindex verifies that the original source of the review is Google. Impressed by the quick cure time of the garage floor coating. Minimal disruption, and I was back to using my garage in no time.